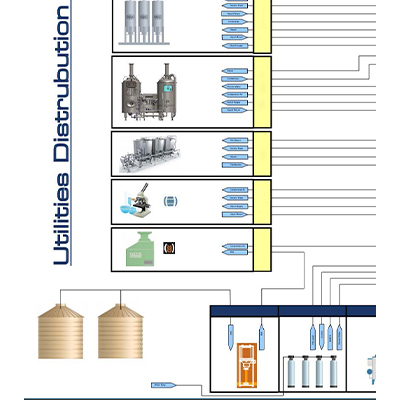

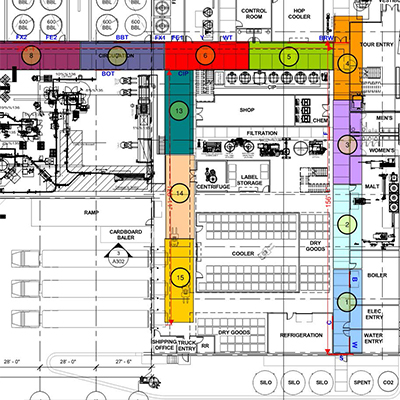

K-Malt provides customers with a turn-key piping solution for integration of both process and utility piping between mechanical and equipment. Our process, brewery, and utility engineering services maximize design and energy efficiencies for all equipment selection throughout the facility.

In addition, we offer brewery-specific process and utility piping and instrumentation diagram/drawings (P&ID) that migrate into a fully detailed 3-D fabrication model. This mitigates on-site piping issues and allows for coordination and sizing of multiple phases of brewery expansion.

The benefits of our highly developed “spine” approach to the piping-bridge design include:

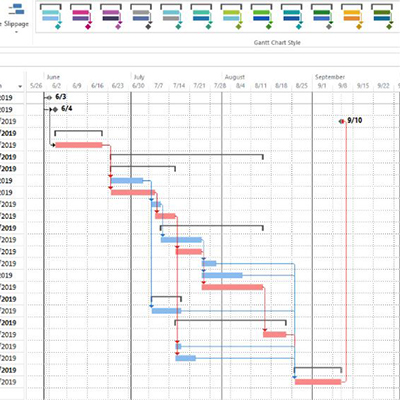

Definitive schedule durations are developed and site delivery logistics are controlled through fabrication management and integration with your overall master construction schedule.

We look forward to the opportunity to partner with you and be a part of your brewery project. Cheers!

Let us quote your project or answer your questions.