K-malt can provide the mechanical installation of all the equipment we offer.

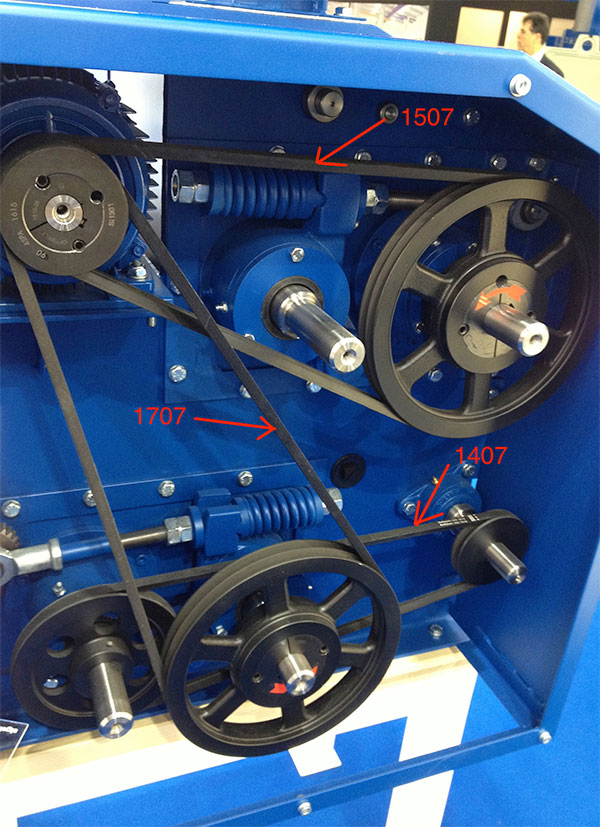

Our Colorado shop maintains an inventory of critical spare parts for all the equipment we supply.

Eliminate whole grains in your grist for lower malt costs & better brew-house efficiency. (Sorry, cows).

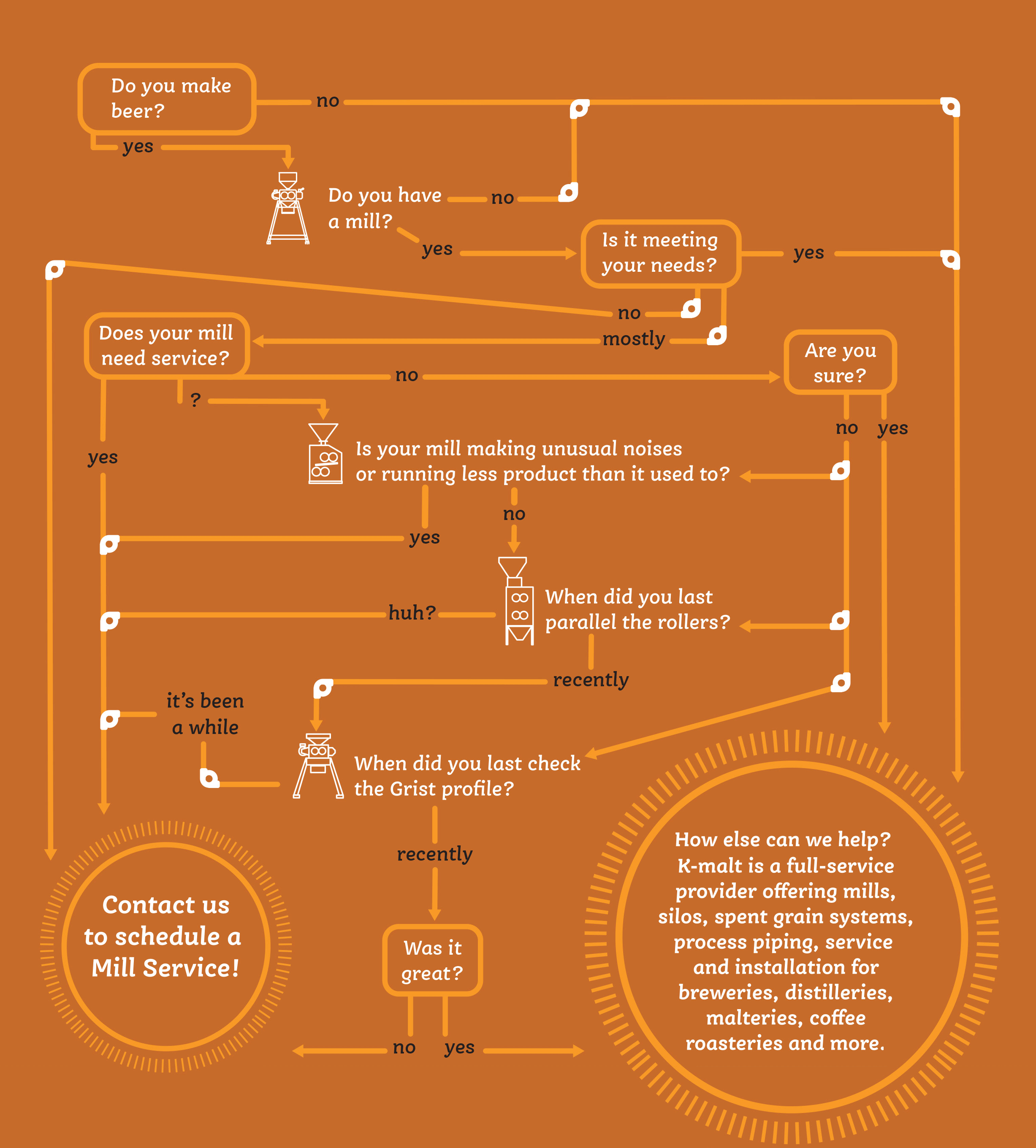

The importance of a good grist composition cannot be understated. Historically, brewers have always understood that to be able to produce a “clear” wort, the filtration, or these days the functioning of the lauter tun, had to meet certain criteria. One of the biggest factors next to a properly sized lauter tun, for both throughput and wort quality, is the grist distribution of the malted barley. The mill has to produce the right distribution (of particles sizes) of the milled malted barley or any other grain used in brewing. This distribution is a function of both malt quality (properly malted grains) as well as the milling of the malted brewing grains. Milling of malted barley is much more the than just the crushing of grains. The use of sieves to properly distribute the grains as well as the use of multiple set of hardened rollers has a big influence on the proper grist distribution. Additionally, brewers can leave a lot of extract behind if they don’t properly mill their grain. This knowledge is present in the design of all Künzel mills with their proven.

Please provide approximately 500 g (17.6 oz) per sample in a ziplock bag.

Send your grist samples to:

K-Malt

390 Mountain View Rd.

Johnstown, CO 80534

Include:

Brewery Name

Mill type and model

Roller gap setting(s)

Grain type

Our malt handling systems work hand-in-hand with the brew house process. As both brewers and engineers, we understand the intricacy of both processes. Let us help you optimize the performance of the complete system so you can make your best beer.

Let us quote your project or answer your questions.